At Integrated Solutions, we specialize in providing high-quality rubber rollers and industrial rollers designed to meet the needs of various industries. Whether you’re in manufacturing, warehousing, aerospace, or automotive, our rubber rolls are custom-engineered to suit your specific applications.

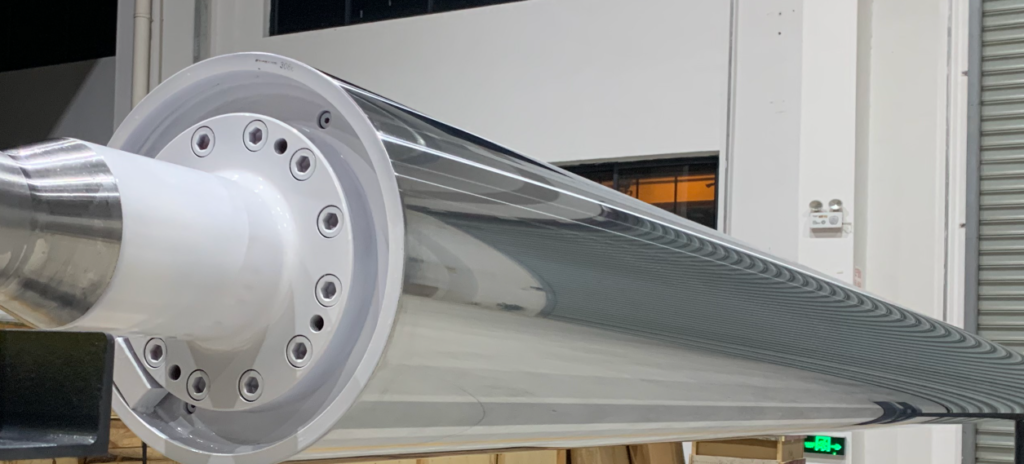

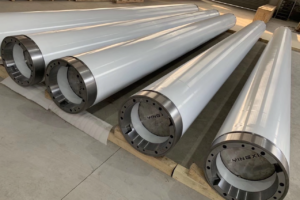

From small-diameter rollers for printers to large, long-length rolls for plastic production, ISI offers a wide range of solutions that ensure durability, performance, and cost-effectiveness. With manufacturing facilities both in the USA and Asia, we are able to deliver superior products at competitive prices, all while maintaining strict quality standards. No matter the size of your order, ISI is committed to providing reliable, high-performance rubber rollers tailored to your exact requirements.

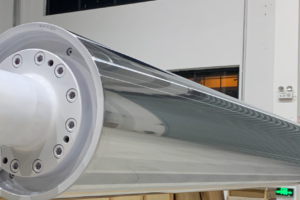

Rubber Covered Rolls

- Neoprene, Silicon, RTV, Urethane, Hypalon, EPDM

- Grooved, Strait, or Spiral

- Strait or Crowned Grind

- ¼” to 36″ in Diameter

- Up to 200″ in Length

- Compression-Molded

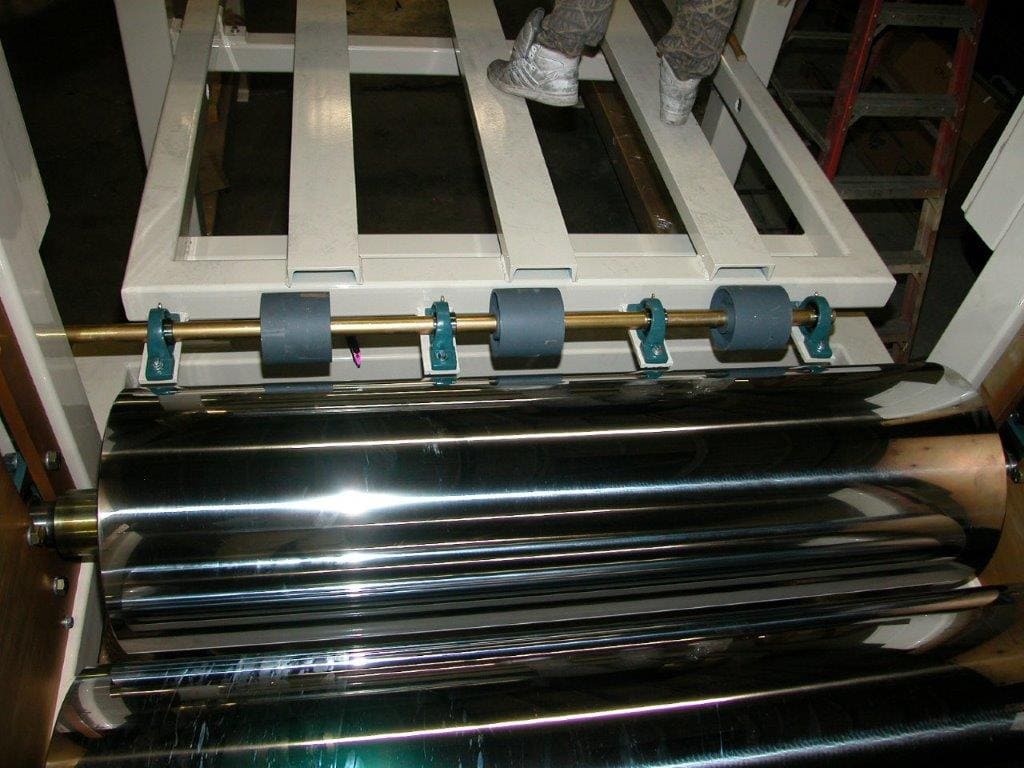

Industrial rollers play a vital role in conveyor operations to direct raw materials, partial components, and finished goods from one production operation to another within a facility. They are also used to form and shape materials, spread coatings, laminate products, and clean equipment and product surfaces.

Integrated Solutions manufactures and distributes a wide variety of rubber rollers and other components for customers in industrial settings.

Rubber Rollers

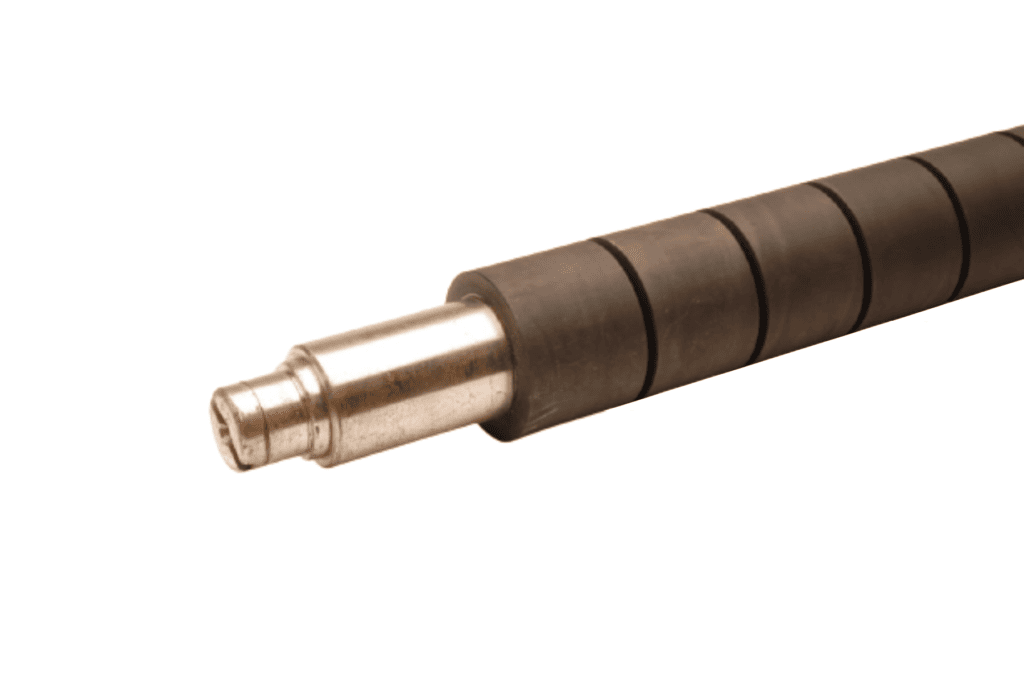

A rubber roller consists of a cylindrical tube or shaft enclosed in a layer of rubber material. The inner core is typically composed of a strong material like steel or aluminum. The outer layer of a rubber roll can be smooth or textured to enhance grip. Rubber-covered rolls have many industrial applications, including smoothing paper and plastic, applying and spreading coatings, texturizing rubber rolls, reducing friction heat, and preventing conveyor slippage. Rubber rollers are a cost-effective solution due to their durability and unique physical properties.

Types of Rubber Rollers

Rubber rollers are available in an assortment of designs and configurations to meet the needs of unique applications. The most common types of rubber rollers are:

- Ink and Printing Rollers: Printing rollers apply writing, figures, images, and designs onto paper and substrates using ink or paint.

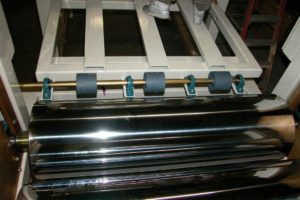

- Laminating Rollers: Laminating rollers apply laminate materials to substrates. The tolerances on these rollers are usually much tighter.

- Drive Rollers: Drive rollers are used to transport materials from one location to another using a series of rollers.

- Guides/Idler Rollers: Idler rollers support and guide roller and conveyor systems by facilitating smooth, continuous motion.

- Grooved Rollers: Straight groves can be used to allow air to pass through, or allow wires or ropes to be installed to keep material from wrapping on the rollers

- Spreader Rollers: Spreader rollers are V or U grooved,starting from the center of the roll. Designed specifically for spreading and smoothing applications. Allowing wrinkles to be spread out as the material is rolled over the roller.

- Conveyor Rollers: Conveyor rollers are used to transport materials from one location to another on a motorized, mechanical, or manual conveyor system.

- Live Shaft Rollers: Live shaft rollers feature external bearings. Ideal for use in heavy load-bearing applications and harsh conditions. The shaft and entire roll rotate together on external bearings.

- Dead Shaft Rollers: Dead shaft rollers use internal bearings which allow the roller to spin around the stationary center shaft. With a dead shaft idler, bearings are installed in each end of the roller body and the shaft passes through the body of the roll. The shaft is mounted to the framework of a machine and the roll body rotates around the fixed shaft. The shaft does not rotate so it is called a dead shaft.

- Cleaning Rollers: Cleaning rollers are designed to perform highly specialized cleaning operations to remove contaminants such as dust, dirt, debris, and liquids.

- Stinger Rollers: Stinger rollers are dead shaft rollers engineered for marine applications.

- Urethane/Polyurethane Rollers: Composed of polyurethane, these rollers are cost-efficient, shock resistant, elastic, and strong.

- EPDM Rollers: EPDM (ethylene propylene diene monomer) rollers are made with a synthetic rubber made up of ethylene, propylene, and diene monomers. EPDM rollers have a higher resistance to heat, oxidation, corrosion, and harsh weather conditions than Neoprene.

- Industrial Rubber Rollers: Industrial rubber rollers are designed for use in industrial and manufacturing operations.

- Nip Rollers: Also called pinch or laminated rollers, nip rollers are used to press several sheets of material together, ultimately forming a laminated product.

Rubber Roller Materials

Rubber rollers are versatile and are manufactured from a range of rubber materials that each have benefits and detriments depending on the application, including:

- Neoprene: Neoprene is a chemically stable synthetic rubber that is resistant to compression and maintains flexibility in a wide range of temperatures. Neoprene is the most common material for rubber rollers and is used on a variety of roller types including nip rollers and conveyor rollers. Neoprene rollers are commonly found in conveyor systems and printing equipment.

- Neoprene plus polyvinyl chloride (PVC): Adds a higher degree of wear resistance than straight neoprene. This combination is commonly used in printing and building applications.

- Silicone Rubber: Silicone rubber is extremely temperature resistant, and has non-stick properties that make it ideal for rollers. Applications include coating, laminating, and extrusion.

- RTV: Room-temperature-vulcanizing (RTV) silicone is a compound that is applied as a liquid and cures at room temperature into a flexible rubber material. RTV silicone is commonly used in the aircraft and aerospace industries.

- Urethane: Urethane, or polyurethane, is highly durable with excellent chemical and wear resistance. These types of rollers are commonly used for material processing in the sheet metal industry.

- Hypalon: Hypalon® is a high-performance synthetic rubber that exhibits high electrical, chemical, thermal, and abrasion resistance. Used in coating, laminating, converting, embossing, and extrusion applications.

- EPDM: Ethylene propylene diene monomer (EPDM) is relatively inexpensive and resistant to chemicals, ozone, and temperature fluctuations. Common uses include coating, flexo printing, and laminating applications.

- PVC: Polyvinyl chloride (PVC) is a thermoplastic material which can be melted down at high temperatures, molded, and cooled again to solid form. PVC can be rigid or flexible. It is strong, lightweight, and durable. This material can be used in wash-down applications and has a sanitary design, making it well suited for the food and beverage and agriculture industries.

Industrial Rollers at Integrated Solutions

Integrated Solutions is committed to providing superior industrial rollers to your specifications. We have experience serving customers in the manufacturing, warehousing, distribution, aerospace, and automotive industries, among others. To learn more about our selection of industrial rollers, contact us today or request a quote.