Excellence in Precision Gear Production

At Integrated Solutions (ISI), we pride ourselves in our commitment to precision gear manufacturing. By utilizing state-of-the-art technology and innovative techniques, we’re able to craft gears for OEMs that embody precision in every aspect.

Through this dedication to exceptional craftsmanship and meticulous attention to detail, we have positioned ourselves as a leader in the industry. As a trusted precision gear manufacturer for OEMs, you can rely on us to exceed expectations and provide gears that enhance the efficiency and performance of your diverse applications.

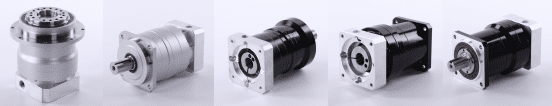

Our Precision Gear Manufacturing Capabilities

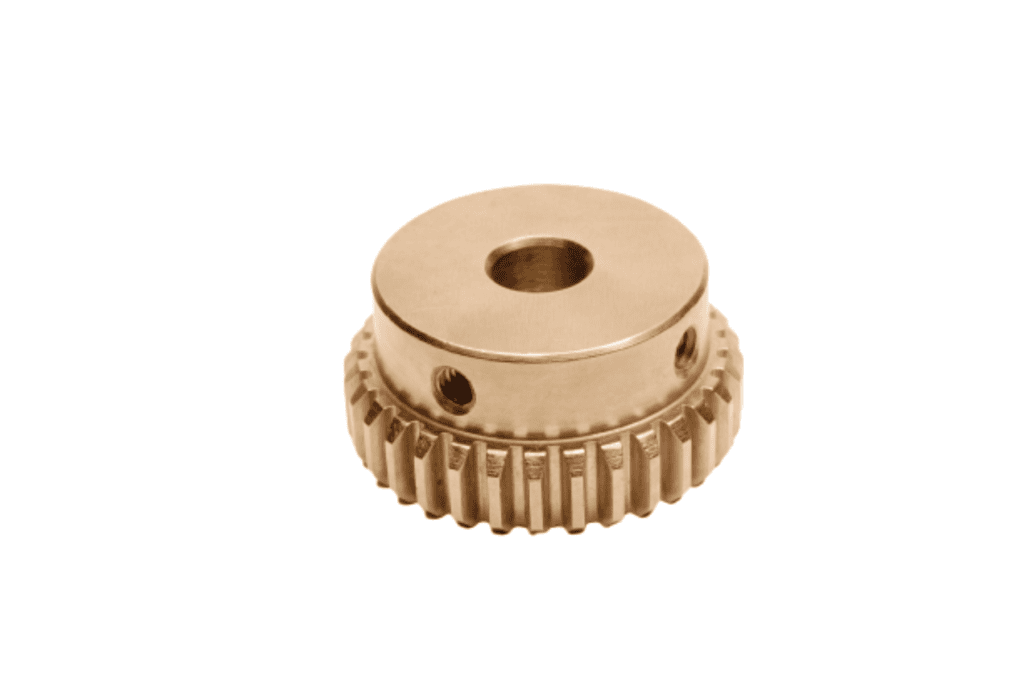

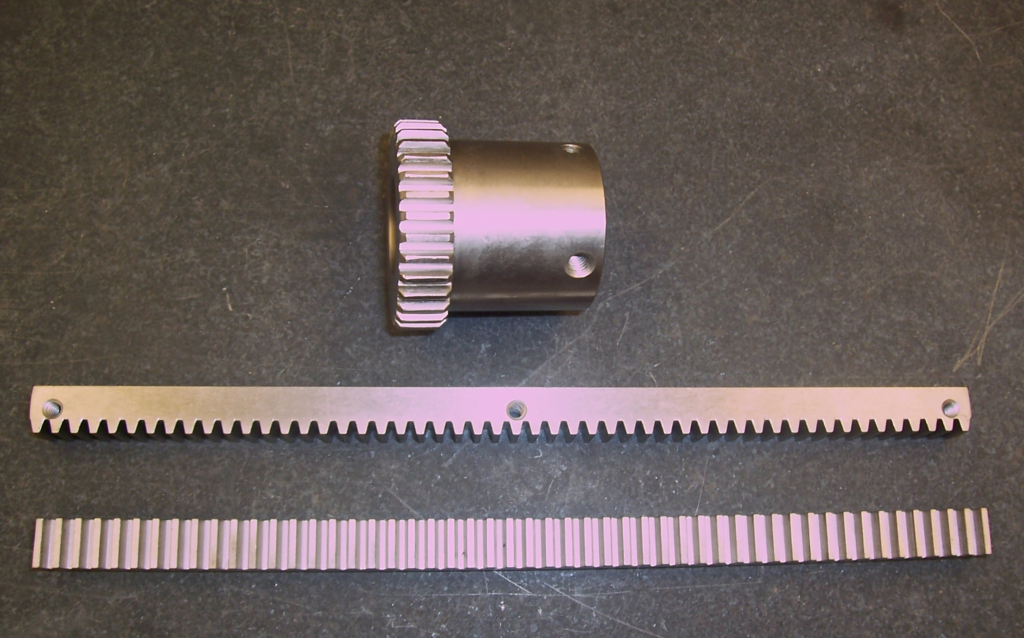

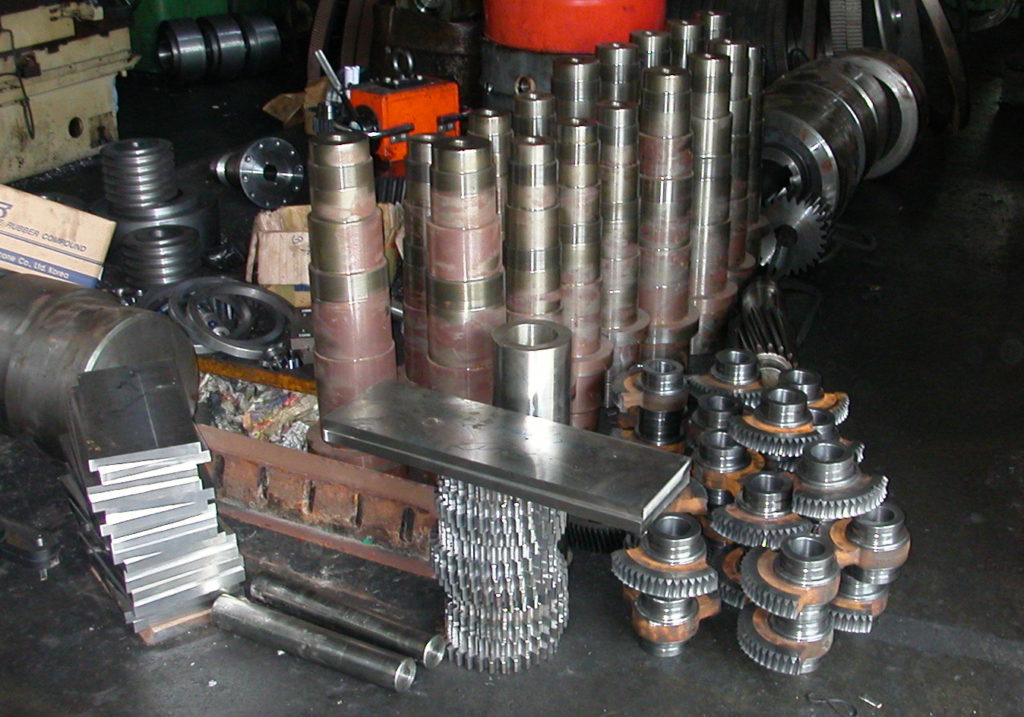

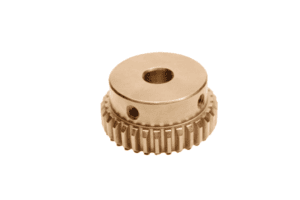

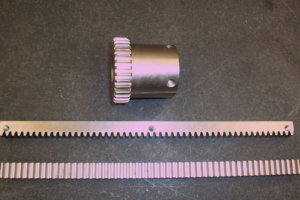

- Diverse Gear Types: We specialize in a wide array of gears, including Acme Lead Screws, Spiral, Helical, Double Helical, Spur, Bevel, Worm Gear, Sprockets, and Spline gears. The variety of these products ensure we can meet the specific needs of your OEM application.

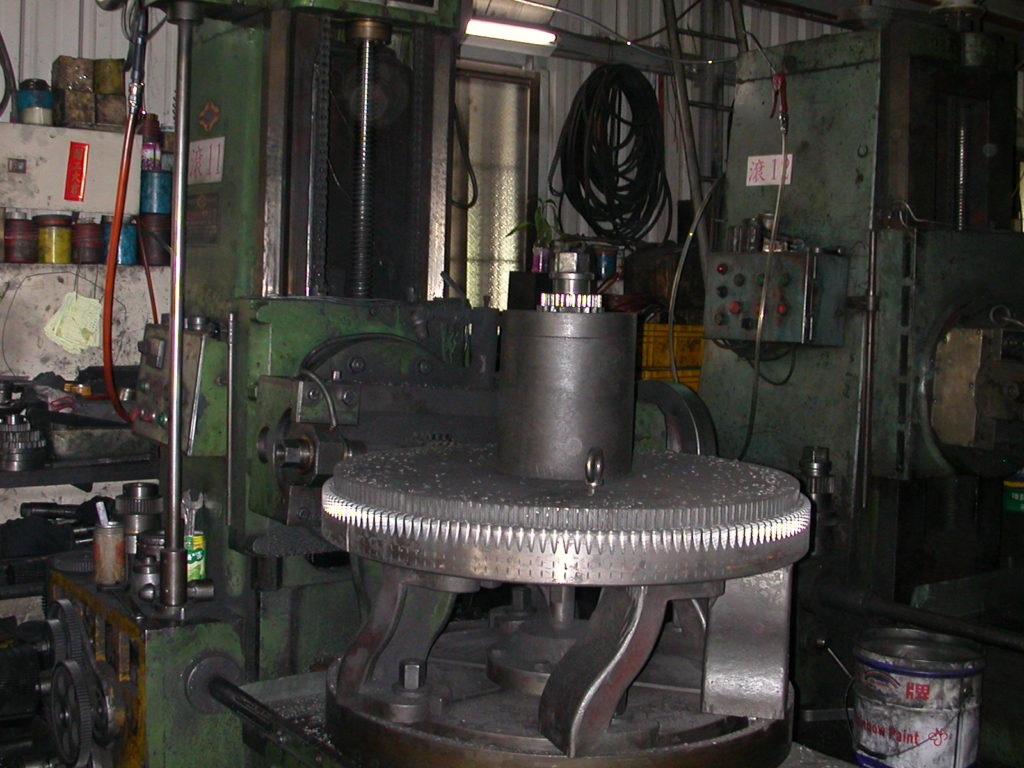

- Advanced Manufacturing Processes: Our manufacturing processes are geared towards producing high-precision gears. These include milling, thread milling, conventional and climb hobbing, EDM (Electrical Discharge Machining), flame-cutting, turning, broaching, essential seating, and shaping.

- Material Versatility: We work with various materials to ensure flexibility and adaptability to your specific material requirements. Our catalog of materials comprises of bronze, stainless steel, cast iron, and plastic.

- Specification Compliance: By being capable of building to both Metric and SAE specifications, we demonstrate our capability to handle diverse dimension requirements.

- Industry-Specific Expertise: Our experience spans across numerous OEM industries. From plastic film, aerospace, and printing to woodworking and manufacturing. This showcases our ability to adapt to the unique demands of different sectors.

Why Choose ISI as Your OEM Precision Gear Manufacturing Company?

- Tailored Solutions: Right from the first step of an OEM project, we engage in print translation and manufacture production according to your precise design specifications. We ensure a custom-tailored approach to every gear.

- Cost-Effective Manufacturing: We prioritize cost-effectiveness without compromising on the quality of our precision gears. As a result, you receive value-driven solutions.

- Quality OEM Gears: Our factories are experienced in creating precision ground or cut gears for OEMs. We guarantee high-quality gears that enhance the reliability and longevity of your OEM products.

- Advanced Technological Integration: We continuously integrate the latest technological advancements into our gear manufacturing process at ISI. By leveraging cutting-edge technology, we can remain at the forefront of precision gear innovation.

- Experienced Team: Our experts possess the knowledge and skills to deliver precision gears that perfectly align with your unique OEM requirements.

- Global Standards Compliance: Adherence to global manufacturing standards is a cornerstone of our process. All our gears meet stringent quality and precision benchmarks, giving you peace of mind knowing that your OEM products are built to the highest standards.

Partner with ISI for Unmatched Precision Gear Solutions

The precision and reliability of ISI’s gear manufacturing services can elevate your OEM operations. With our roots in bridging overseas manufacturing expertise to local demands, we are able to provide top-notch and cost-effective products. Whether you require intricate helical gears or robust spur gears, we are here to help you succeed.

Contact us today to discover how our precision gear manufacturing can propel your OEM projects to new heights. With ISI, precision is not just a promise – it’s a guarantee.