Electroplating racks are instrumental for holding and positioning parts during the electroplating process. Their design allows optimum surface area exposure, which is essential for uniform coating applications. These racks are fabricated from materials compatible with the electroplating solution to prevent corrosion and contamination.

ISI supports businesses that specialize in electroplating services by supplying racks and baskets for manual and automatic electroplating lines. We also specialize in manufacturing parts in plastic, rubber, and fiberglass and retrofitting them to work with our client’s new or current products.

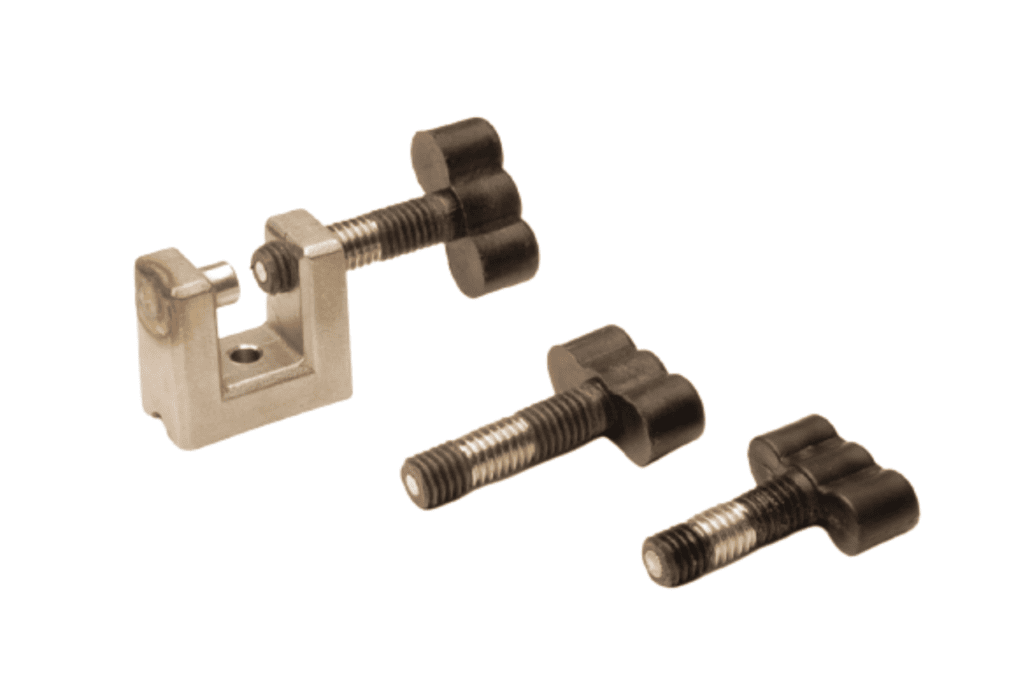

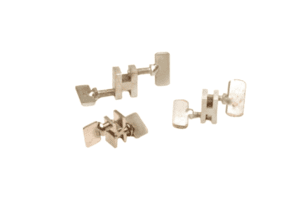

Electroplating Racks

Electroplating racks are manufactured for the purpose of holding parts in electroplating services, to make sure that electric current can flow through the material.

Manufactured from conductive materials, these racks allow an efficient current flow to the electroplating equipment. They are especially crucial for parts requiring precise plating thickness, minimal contact marks, and uniform coverage.

Some benefits of electroplating racks include:

- Enhance plating quality through consistent electrical contact

- Reduce waste by minimizing excess plating on non-critical areas

- Custom configurations to accommodate a variety of part sizes and shapes

Numerous electroplating companies, namely the aerospace, architecture, and electronics industries, have benefited from ISI’s industrial electroplating racks.

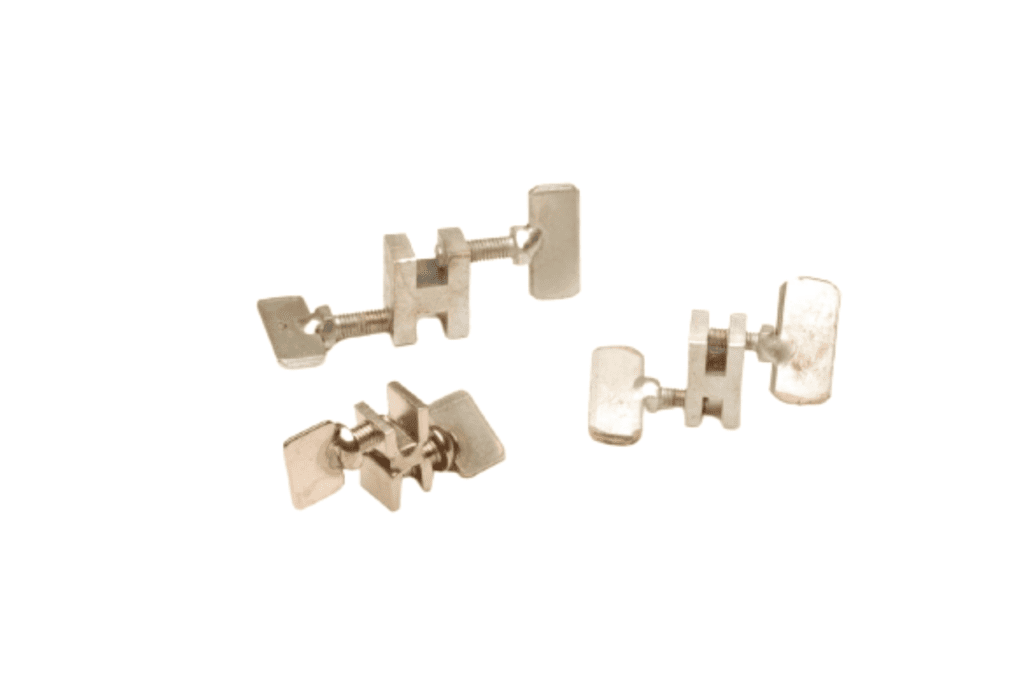

Electroplating Baskets

Electroplating baskets are containers with holes used in electroplating services to ensure that small components, such as screws, washers, and pins, receive an even coating without sticking together.

These come in various shapes and sizes, made of materials such as polypropylene plastic, titanium, and copper. They are designed to ensure efficient and high-quality plating results.

Other benefits of electroplating baskets include:

- Increased throughput by plating multiple parts in one session

- Improved process efficiency with easy loading and unloading

- Versatility for use in both manual and automated plating systems

Our team can modify and rebuild stainless steel, zirconium, or titanium racks and baskets, and tailor fit them for new or existing products for industrial electroplating.

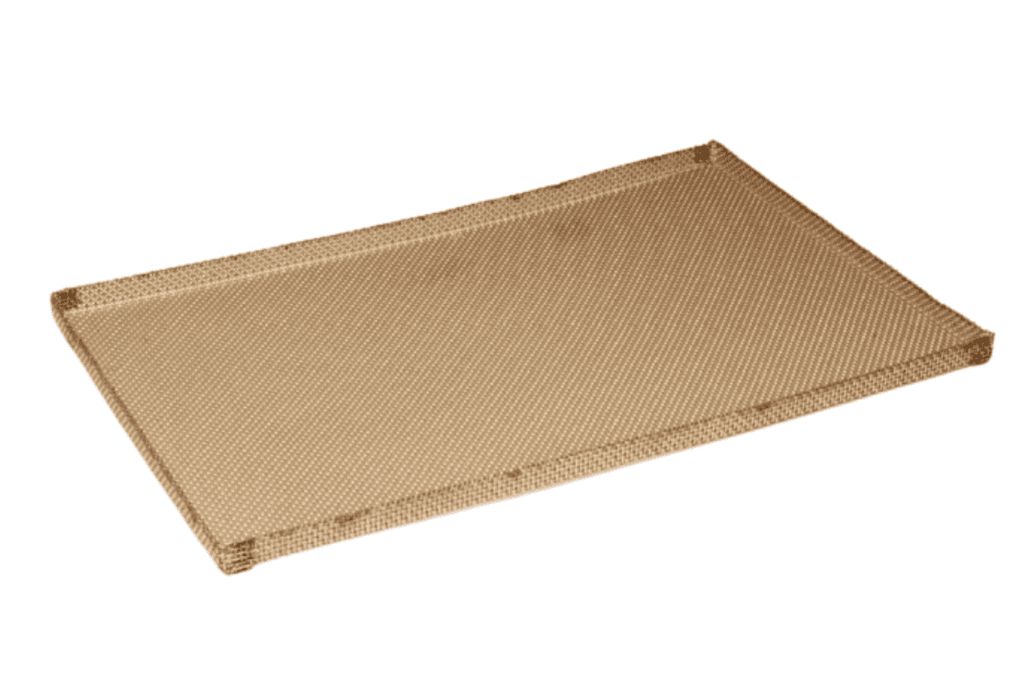

What’s the Purpose of Plastisol Coating

Electroplating companies that want multiple uses for their electroplating racks and baskets can have them coated in plastisol. Plastisol is a type of vinyl material that’s widely used in the electroplating process to protect racks from the dipping process. At ISI, we can also recoat your old racks with plastisol so you can cut costs and improve your bottom line.

Some benefits of plastisol coating include:

- Chemical and electrical resistance

- Impact and abrasion resistance

- Thermal stability

- Weather resistance

- Corrosion resistance

- Extends the life of racks and baskets

Plastisol coating also provides insulation for racks and baskets. This coating is available in various colors, allowing electroplating companies to color code their racks and baskets for easy identification and organization.

Trust ISI to Deliver Quality Electroplating Supplies

At ISI, our specialty is supporting electroplating companies with quality parts and equipment. We are dedicated to providing customized solutions for your particular products, ensuring maximum efficiency and cost-effectiveness.

Contact us today to learn more about our services. You may also request a quote, and we can develop a unique solution tailored to your needs!