ISI is a leading overseas manufacturer that produces high-quality induction heating coils. Our team can customize an induction heating coil based on your project’s specifications and applications, ensuring it functions according to its intended purpose. With our cutting-edge equipment and fully equipped facility, we can deliver heat induction coil solutions that will support your production process.

What is an Induction Heater Coil?

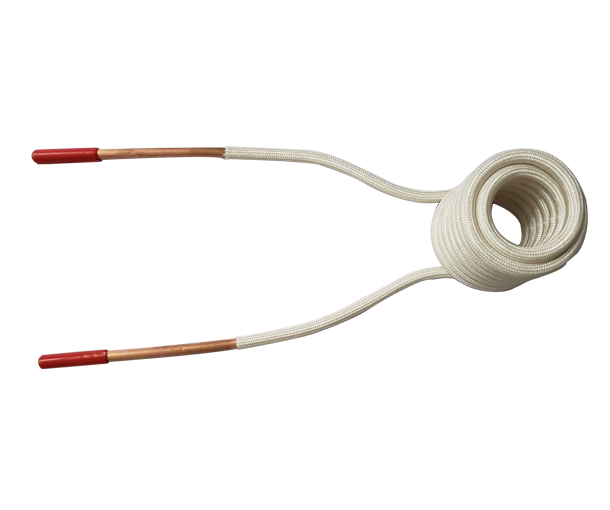

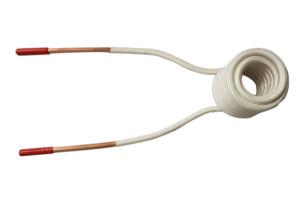

A heat induction coil is made with water-cooled copper conductors formed into coil shapes for the induction heating process. The coils don’t get hot as the water flows through them, allowing the coil to stay cool while producing high-frequency magnetic fields that induce heat in electrically conductive materials.

These coils are essential in the induction heating process and are crucial in ensuring effective and efficient heat transfer. Therefore, the design must be made for each specific application to achieve the desired results and guarantee the efficacy of the heating process.

What are the Benefits of Using an Induction Coil Heater?

For most induction heating processes, induction heating coils are the most viable, with substantial benefits that can improve your bottom line. A quick overview of its advantages is as follows:

- Rapid Heating: Induction heating is a quick process that can heat materials in seconds without any preheating time.

- Precise heating: Induction heating coils are excellent for localized heating, ensuring only the desired area reaches the required temperature.

- Energy efficiency: As an induction heater coil works directly on the material, there’s minimal heat loss during the process, making it energy-efficient and saving.

- Best quality and yield: Induction heating coils provide uniform and even heating throughout the material, ensuring quality and yield are maintained and consistent.

- Safe to use: The induction heat coil process is secure, as there’s no open flame or contact between the coil and the heated material.

Applications of an Induction Heating Coil

Numerous demanding industries rely on induction heating coils. Because of its versatility, it has become a popular method in various induction heating applications, including:

- Metalworking: Forging, brazing, annealing, and hardening are common manufacturing methods in metalworking applications. An induction coil heater is used during these procedures because it offers precision and control.

- Automotive: In vehicle manufacturing and assembly, induction heating is notably employed in various operations, from component production to assembly line operations.

- Petrochemical: Heat induction coil solutions are predominantly used during heat treatment, polymerization, pipe welding, and other petrochemical processes.

- Aerospace: Fabricating critical aerospace components is facilitated through induction heating using a specialized induction heater coil.

- Brazing

- Soldering

- Insert Heating Pressing into Plastics

- Shrink Fitting Gears

- Shrink Fitting Rings

- Shrink Fitting Bearings

- Pre Heating for Welding

- Molding Applications

- Melting

- Heat Staking

- Cap Sealing

- Extruder Barrel Heating

- Curing Coatings

- Curing Adhesives

- Annealing

- Stress Relieving

- Process Heating

- Heat Treating

- Insert Heating

- Electromagnetic Heating

- Induction Heater

- Induction Heating Controls

- Jewelry Casting

- Dental Casting

- Melting

- Casting

- Billet Forging

- Hardening

- Getter Firing

- Relieving

- Wire Heating

- Cable Heating

- Crystal Growing

- Gold Casting

- Silver Casting

- Water-cooled Induction Coil

Optimize Your Induction Heating Process with Induction Heating Coils

Our high-quality induction heat coil solutions will enhance your operations and streamline your production processes. Made with outstanding designs and developed by professionals with years of experience, you can trust us to deliver outcomes that will drive the success of your projects.

If you want to know more about ISI’s capabilities and services, don’t hesitate to contact us today. You may also request a quote, and our team can find a cost-effective solution tailored to your unique needs and requirements!